A BIG PICTURE APPROACH

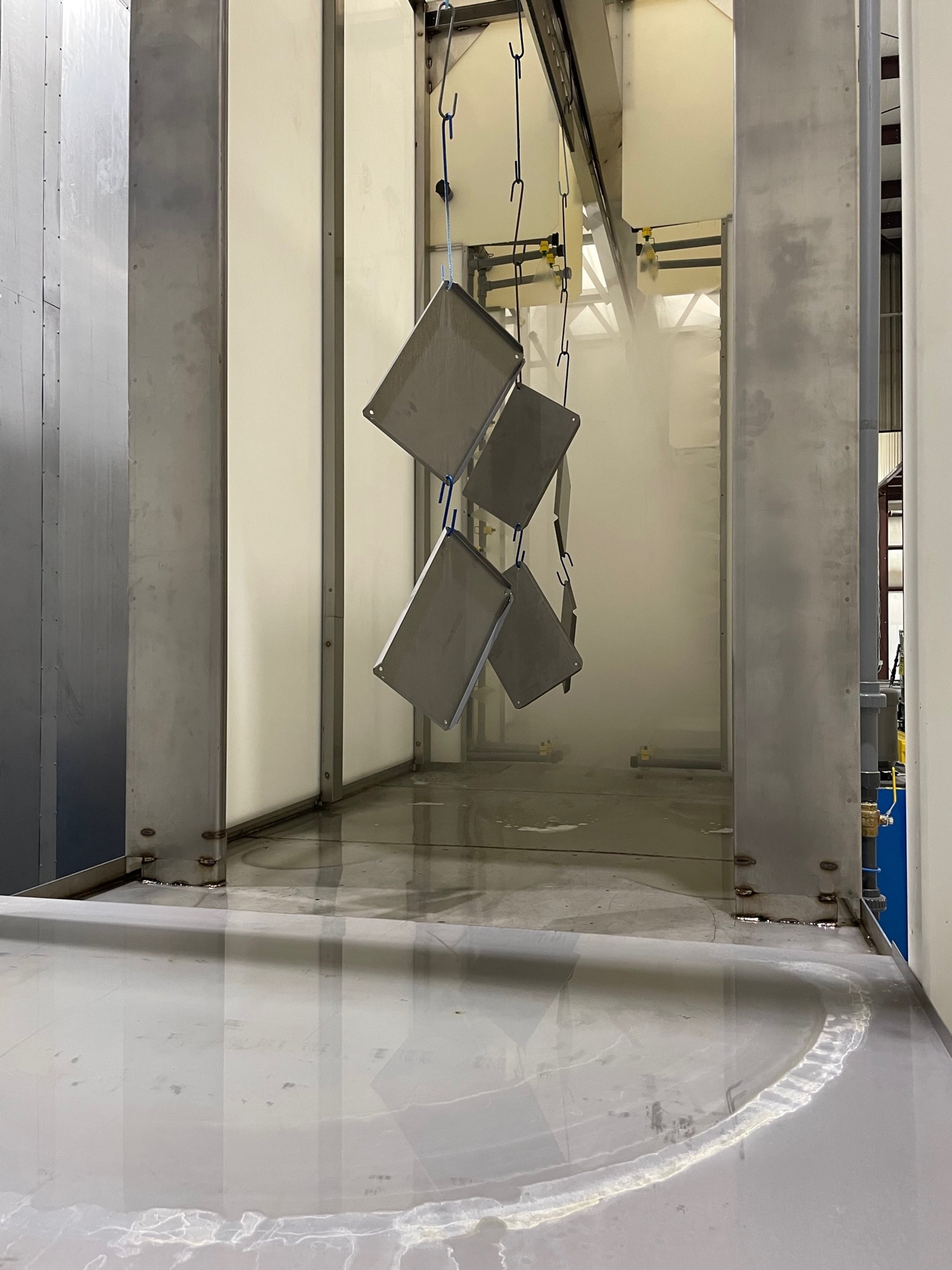

With more than 50 years of experience, Troy Chemical is a leading ISO Certified Manufacturer of Pretreatment Chemicals. Our proven products have helped several powder coating and liquid paint lines over the years reach and maintain their quality objectives. We pride ourselves on our high level of service and our ability to meet the ever-changing demands of the finishing industry.

Our products encompass:

Alkaline Cleaners

Neutral to heavy duty caustic based

Recirculating & Spray Wand

Phosphate Coatings

Cleaner / Phosphatizers

Phosphatizers only

Heavy metal free

Recirculating & Spray Wand

Zirconium Coatings

Combination cleaner / coater

Coater only

Recirculating & Spray Wand

Laser scale removers

Liquids & gels

Sealers

Rust Preventatives

Salt spray promoter

Our KOOLBLUE designated products are ideal for use in Pretreatment systems. These products are produced to reduce your environmental impact. Examples are:

Environmentally friendly chemistry

A reduction of operating temperatures

Reduction of water consumption

Tanks eliminated from your process

Elimination of phosphates

Reduction of operating costs

Anything that reduces your carbon footprint is what our KOOLBLUE line of products will help our partners achieve. As a result, our customers are more profitable. Combining our Big Picture Approach and our KOOLBLUE chemistry is an outstanding combination for our partners.

While our products stand on their own, we feel our ability to take a big picture approach is what sets us apart. Our ability of observing YOUR process and then implementing the correct chemistry along with the proper use dilutions is a strength of ours. We will be a part of your quality team and want to be aware of any potential process changes that may impact the Pretreatment process.

Training & Support

Troy Chemical welcomes any opportunity to earn your business. In order for us to be effective for our customers, we must first understand where the current process is as well as the ideal objectives that need to be met. Troy Chemical will observe your operation, listen to your issues and will meet with our lab to determine the best course of action.

We will know your process; we will train your personnel; we will partner with your team.

Troy Chemical representatives are all Pretreatment Certified. Every rep has been through Pretreatment Chemical classes as well as field training. Reps are tested on an ongoing basis in order to provide continuous support to their customers. We understand that we’ll need to train personnel that may not have a vast understanding of your process. We understand that we’ll need to work with other vendors to collaborate on various issues. Our team members will provide knowledge and will be a great resource to have on your quality team.